Factory Supply Prefabricated Steel Structure Building with High Quality

Qingdao Beiyuan concrete tank closure, raw material warehouse steel structure project

Qingdao Beiyuan concrete tank closure, raw material warehouse steel structure project

The total construction area is 16,325.1 square meters, of which the raw material warehouse area is about 13,000 square meters, and the area of the two tanks is about 3,325 square meters. The height of the eaves of the tank body is 31.95m, the total height is 33.575m, and the height of the cornice of the belt gallery is 15.481m; the total height is 18.555m.

Company information :

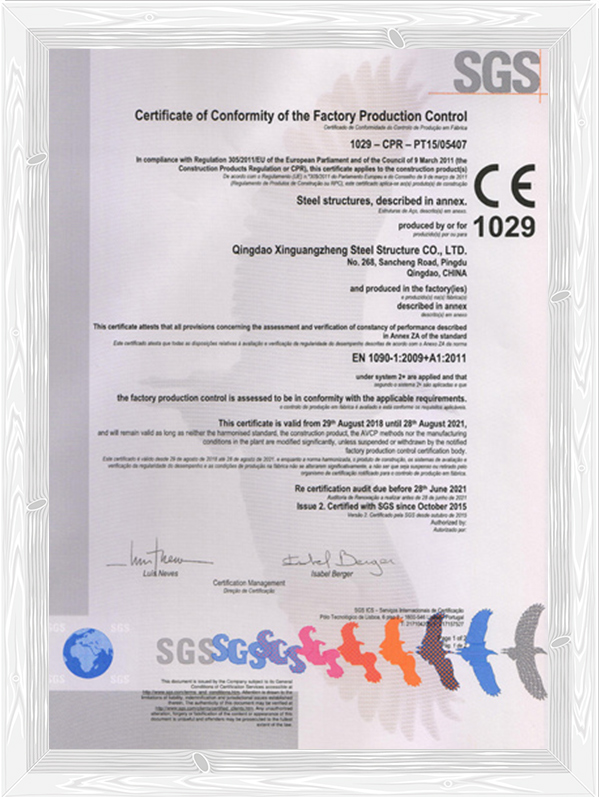

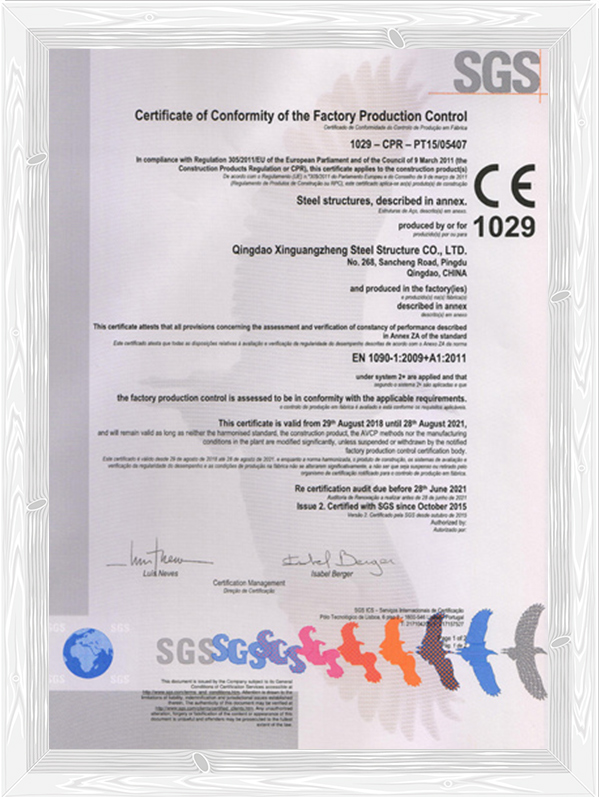

Qingdao Xinguangzheng Steel Structure Co., Ltd. is an enterprise specializing in the production of steel structure Bridges, steel structure workshop, exhibition hall, warehouse, assembly room, container room, intelligent animal husbandry equipment and other steel structure products. It has 25 years of experience and has obtained CE.ISO.BV and TUV certification.

The prefabricated steel structure building has the advantages of large spanning capacity, lightweight, fast construction speed, no leakage, and long service life. Its outstanding feature is to adapt to unsupported spans, suitable for warehouses, workshops, factories, exhibition halls, breeding plants, auditoriums, libraries, classrooms, lecture halls, cultural and sports venues, bazaars, residences, prefabricated building etc.

1) Rich expert group experience

Our employees with more than 20 years of experience have received professional training and testing. We can customize or design according to your drawings and requirements to provide satisfactory solutions.

2) Advanced tools

Equipped with more than 80 sets of precision repairing machines such as large-scale planers, automatic arc welding machines, assembly machines, sliders, and firing machines.

3) Strict quality control, check all product connections

Each workshop has some quality inspectors to inspect and evaluate the products.

4) Installed before sending

After assembling the first batch of products, test the assembly, and if appropriate, continue the assembly.

5) Timely delivery.

25 to 60 days after confirming the order, depending on the quantity of the product.

1. How to buy your idea products?

A: TT and L/C are acceptable and TT will be more appreciated. 50% deposit before producing, balance before loading by TT.

Project scope

1.Industrial plane/workshop/warehouse/factories, airport terminal, highrise building, bridge, exhibition hall, stadium and so on.

2.We can also develop and produce new parts according to your requirements.

2.What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 15 to 30 days.

3. How to pack the products?

A: We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

4.How to install after the goods arriving destination?

A: We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

As the demand for prefabricated steel structures rises, so does supply. From factory areas to warehouses, steel structures are now in high demand, thanks to their durability and cost-effectiveness. But there are a lot of factors that go into purchasing quality prefabricated steel structures, including safety standards, installation costs, and more. In this blog post, we'll explore the many aspects of factory supply prefabricated steel structure building with high quality. From materials to design considerations and regulatory requirements, you’ll have all the information you need to make an educated decision when it comes to these crucial investments.

There are many advantages of prefabricated steel buildings over other types of construction. Steel is much stronger than wood, so prefabricated buildings can be designed to be much taller and larger without sacrificing structural integrity. Steel is also more durable than wood, so prefabricated buildings will last longer and require less maintenance over time. Additionally, steel is fireproof and termite-resistant, making it a very safe building material.

Prefabricated steel buildings are also very energy efficient. Steel framing is well insulated and provides a tight seal against the elements, so prefabricated buildings stay cooler in the summer and warmer in the winter. This can save a significant amount of money on heating and cooling costs over the lifetime of the building.

Overall, prefabricated steel buildings offer a high quality, durable, and energy-efficient option for any type of construction project.

There are many factors to consider when choosing a prefabricated steel structure building, including the technical parameters. Here are some important technical parameters to keep in mind when making your decision:

1. Wind load: The wind load is the amount of force that the wind can exert on the building. The higher the wind load, the more sturdy the building must be.

2. Snow load: The snow load is the amount of weight that the snow can put on the building. The higher the snow load, the more sturdy the building must be.

3. Earthquake resistance: The earthquake resistance is the ability of the building to withstand earthquakes. The higher the earthquake resistance, the more safe and durable the building will be.

4. Heat insulation: The heat insulation is the ability of the building to keep heat in or out, depending on your needs. The better the heat insulation, the more comfortable it will be inside your prefabricated steel structure building.

5. Sound insulation: The sound insulation is the ability of the building to keep noise levels down. The better the sound insulation, the quieter it will be inside your prefabricated steel structure building

One of the benefits of prefabricated steel buildings is that they can be used for a variety of purposes. Whether you need a storage shed, workshop, or commercial building, prefabricated steel buildings are a versatile and affordable solution.

Here are some common uses for prefabricated steel buildings:

1. Storage Sheds

Prefabricated steel buildings make great storage sheds because they are durable and weatherproof. You can use them to store garden tools, lawn equipment, or anything else you need to keep safe from the elements.

2. Workshops

A prefabricated steel building is the perfect place to set up a workshop. You’ll have plenty of space for all your tools and materials, and you can customize the interior to suit your needs.

3. Garages

If you need more space for your cars or other vehicles, a prefabricated steel garage is a great solution. You can also use it to store bikes, motorcycles, ATVs, or any other type of equipment.

4. Commercial Buildings

Prefabricated steel buildings can be used for a variety of commercial purposes, such as office space, retail stores, warehouses, and more. They are durable and easy to customize, making them an ideal choice for businesses.

Product Operation Guide

In order to ensure the quality of your prefabricated steel structure building, please follow these operation instructions:

1. Before installation, all components should be checked for damage and deformation. If any damage is found, please do not install the damaged component but contact us for replacement.

2. During installation, it is important to follow the assembly drawings and instructions strictly. Do not make any changes to the structure without prior approval.

3. After installation, all connections should be checked for tightness and stability. Make sure that there is no looseness or movement in any part of the structure.

Factory Supply Prefabricated Steel Structure Building with High Quality

Qingdao Beiyuan concrete tank closure, raw material warehouse steel structure project

Qingdao Beiyuan concrete tank closure, raw material warehouse steel structure project

The total construction area is 16,325.1 square meters, of which the raw material warehouse area is about 13,000 square meters, and the area of the two tanks is about 3,325 square meters. The height of the eaves of the tank body is 31.95m, the total height is 33.575m, and the height of the cornice of the belt gallery is 15.481m; the total height is 18.555m.

Company information :

Qingdao Xinguangzheng Steel Structure Co., Ltd. is an enterprise specializing in the production of steel structure Bridges, steel structure workshop, exhibition hall, warehouse, assembly room, container room, intelligent animal husbandry equipment and other steel structure products. It has 25 years of experience and has obtained CE.ISO.BV and TUV certification.

The prefabricated steel structure building has the advantages of large spanning capacity, lightweight, fast construction speed, no leakage, and long service life. Its outstanding feature is to adapt to unsupported spans, suitable for warehouses, workshops, factories, exhibition halls, breeding plants, auditoriums, libraries, classrooms, lecture halls, cultural and sports venues, bazaars, residences, prefabricated building etc.

1) Rich expert group experience

Our employees with more than 20 years of experience have received professional training and testing. We can customize or design according to your drawings and requirements to provide satisfactory solutions.

2) Advanced tools

Equipped with more than 80 sets of precision repairing machines such as large-scale planers, automatic arc welding machines, assembly machines, sliders, and firing machines.

3) Strict quality control, check all product connections

Each workshop has some quality inspectors to inspect and evaluate the products.

4) Installed before sending

After assembling the first batch of products, test the assembly, and if appropriate, continue the assembly.

5) Timely delivery.

25 to 60 days after confirming the order, depending on the quantity of the product.

1. How to buy your idea products?

A: TT and L/C are acceptable and TT will be more appreciated. 50% deposit before producing, balance before loading by TT.

Project scope

1.Industrial plane/workshop/warehouse/factories, airport terminal, highrise building, bridge, exhibition hall, stadium and so on.

2.We can also develop and produce new parts according to your requirements.

2.What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 15 to 30 days.

3. How to pack the products?

A: We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

4.How to install after the goods arriving destination?

A: We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

As the demand for prefabricated steel structures rises, so does supply. From factory areas to warehouses, steel structures are now in high demand, thanks to their durability and cost-effectiveness. But there are a lot of factors that go into purchasing quality prefabricated steel structures, including safety standards, installation costs, and more. In this blog post, we'll explore the many aspects of factory supply prefabricated steel structure building with high quality. From materials to design considerations and regulatory requirements, you’ll have all the information you need to make an educated decision when it comes to these crucial investments.

There are many advantages of prefabricated steel buildings over other types of construction. Steel is much stronger than wood, so prefabricated buildings can be designed to be much taller and larger without sacrificing structural integrity. Steel is also more durable than wood, so prefabricated buildings will last longer and require less maintenance over time. Additionally, steel is fireproof and termite-resistant, making it a very safe building material.

Prefabricated steel buildings are also very energy efficient. Steel framing is well insulated and provides a tight seal against the elements, so prefabricated buildings stay cooler in the summer and warmer in the winter. This can save a significant amount of money on heating and cooling costs over the lifetime of the building.

Overall, prefabricated steel buildings offer a high quality, durable, and energy-efficient option for any type of construction project.

There are many factors to consider when choosing a prefabricated steel structure building, including the technical parameters. Here are some important technical parameters to keep in mind when making your decision:

1. Wind load: The wind load is the amount of force that the wind can exert on the building. The higher the wind load, the more sturdy the building must be.

2. Snow load: The snow load is the amount of weight that the snow can put on the building. The higher the snow load, the more sturdy the building must be.

3. Earthquake resistance: The earthquake resistance is the ability of the building to withstand earthquakes. The higher the earthquake resistance, the more safe and durable the building will be.

4. Heat insulation: The heat insulation is the ability of the building to keep heat in or out, depending on your needs. The better the heat insulation, the more comfortable it will be inside your prefabricated steel structure building.

5. Sound insulation: The sound insulation is the ability of the building to keep noise levels down. The better the sound insulation, the quieter it will be inside your prefabricated steel structure building

One of the benefits of prefabricated steel buildings is that they can be used for a variety of purposes. Whether you need a storage shed, workshop, or commercial building, prefabricated steel buildings are a versatile and affordable solution.

Here are some common uses for prefabricated steel buildings:

1. Storage Sheds

Prefabricated steel buildings make great storage sheds because they are durable and weatherproof. You can use them to store garden tools, lawn equipment, or anything else you need to keep safe from the elements.

2. Workshops

A prefabricated steel building is the perfect place to set up a workshop. You’ll have plenty of space for all your tools and materials, and you can customize the interior to suit your needs.

3. Garages

If you need more space for your cars or other vehicles, a prefabricated steel garage is a great solution. You can also use it to store bikes, motorcycles, ATVs, or any other type of equipment.

4. Commercial Buildings

Prefabricated steel buildings can be used for a variety of commercial purposes, such as office space, retail stores, warehouses, and more. They are durable and easy to customize, making them an ideal choice for businesses.

Product Operation Guide

In order to ensure the quality of your prefabricated steel structure building, please follow these operation instructions:

1. Before installation, all components should be checked for damage and deformation. If any damage is found, please do not install the damaged component but contact us for replacement.

2. During installation, it is important to follow the assembly drawings and instructions strictly. Do not make any changes to the structure without prior approval.

3. After installation, all connections should be checked for tightness and stability. Make sure that there is no looseness or movement in any part of the structure.